Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Silicone Oil Production Line

-

≥1/set

USD 150,000.00

1. Introduction to Silicone Oil

Silicone oil is a versatile linear synthetic polymer belonging to the larger family of silicone (polysiloxane) fluids. Its backbone consists of alternating silicon (Si) and oxygen (O) atoms, a structure that grants it unique properties not found in organic oils.

The basic chemical structure is: R₂SiO(R₂SiO)ₙSiR₂

Where:

-

-SiO-is the repeating inorganic backbone, responsible for thermal stability and flexibility. -

Ris an organic side group, most commonly a methyl group (-CH₃), which is why Polydimethylsiloxane (PDMS) is the most common type of silicone oil. TheRgroup can be modified (e.g., with phenyl, vinyl, or amino groups) to impart specific properties.

Key Characteristics and Properties:

-

Excellent Thermal Stability: Stable over a wide temperature range (-40°C to 200°C+ for standard types, and even higher for specialized grades).

-

Low Surface Tension: Allows them to spread easily and act as great wetting agents, release agents, and surfactants.

-

High Lubricity: Provides smooth lubrication and has a low coefficient of friction.

-

Chemical Inertness: Resistant to water, oxidation, and many chemicals.

-

Weather and UV Resistance: Does not easily degrade when exposed to sunlight or ozone.

-

Physiologically Inert: High-purity grades are non-toxic and hypoallergenic, making them suitable for cosmetic and medical applications.

-

Shear Stability: Viscosity changes very little under mechanical stress.

-

Water Repellency: The methyl groups create a hydrophobic surface.

Common Applications:

-

Industrial: Lubricants, release agents (e.g., for molding tires, baking, plastics), damping fluids, hydraulic fluids, antifoaming agents.

-

Cosmetics and Personal Care: Key ingredient in shampoos, conditioners (for shine and detangling), lotions, creams, and makeup (as a emollient and texture enhancer).

-

Medical: Lubricants for syringes and needles, fluid in breast implants, excipient in topical pharmaceuticals.

-

Electronics: Heat transfer fluids, lubricants for delicate components.

-

Automotive: Polishes, lubricants for components, and in some shock absorbers.

-

Textiles: Softeners and water repellents for fabrics

2. Raw Materials

The production of silicone oil starts from a few fundamental raw materials, primarily derived from sand (silica).

-

Silica (SiO₂): Mined from quartz sand. This is the ultimate source of silicon.

-

Methyl Chloride (CH₃Cl): A chlorinated hydrocarbon gas.

-

Water (H₂O): Used in hydrolysis reactions.

-

Catalysts: Such as sulfuric acid (H₂SO₄) or potassium hydroxide (KOH), used to control polymerization.

-

End-blocking Reagents (Optional): Compounds like hexamethyldisilazane or trimethylchlorosilane are used to "cap" the ends of the polymer chains to control reactivity and final viscosity.

The first critical step is to react silica with carbon and chlorine (via a complex process) to create chlorosilanes, the direct monomers for silicone production. The most important monomer is:

-

Dimethyldichlorosilane ((CH₃)₂SiCl₂): This is the primary building block for most silicone polymers, including PDMS oil. Other chlorosilanes like trimethylchlorosilane ((CH₃)₃SiCl) are used as "end-blockers" to control chain length.

3. Production Steps

The manufacturing process is a multi-step synthesis.

Step 1: Synthesis of Chlorosilane Monomers (The Rochow Process)

This is the foundation of the entire silicone industry.

-

Reaction: Powdered silicon (Si) metal, derived from silica, is reacted with methyl chloride (CH₃Cl) gas in the presence of a copper catalyst at high temperature (~300°C).

-

Product: A mixture of different chlorosilanes is produced, primarily dimethyldichlorosilane. This mixture is then carefully separated by fractional distillation.

Step 2: Hydrolysis

-

Reaction: The purified dimethyldichlorosilane is reacted with water.

-

Product: The chlorine atoms are replaced with hydroxyl (OH) groups, creating a reactive intermediate called dimethylsilanol and hydrochloric acid (HCl) as a byproduct. The silanol molecules instantly condense with each other to form a mixture of linear and cyclic siloxane oligomers (short chains) and polymers.

Step 3: Polymerization ("Cracking" and Re-polymerization)

This step determines the final viscosity (molecular weight) of the silicone oil.

-

Process: The siloxane mixture from hydrolysis is heated with a catalyst (e.g., KOH). This "cracks" the cyclic structures and breaks down the polymers into a thermodynamic equilibrium mixture.

-

Chain Control: An end-blocking agent like trimethylchlorosilane is added. This reagent caps the ends of the growing polymer chains, preventing them from linking together into a gel or rubber. The amount of end-blocker added directly controls the final length of the polymer chains, and thus the oil's viscosity.

TGM Chemical Machine Co., Ltd is a group enterprise. We have brands like TGM, Pengchang and Tongpeng.

We are a leader in the field of chemical machine industry, with 18 years of industry experience.

We have professional R&D design team, strong technical support, skilled production team, reliable after sales service, flexible customized solutions,

to meet your various standards and non standard equipment procurement needs. We committed to providing the complete and professional chemical equipment solutions.

We integrate, design, development, production, sales and training together.

Our products scope: Disperser, Bead Mill, Basket Mill, Mixer, emulsifier, Mixing kettles, Reactor, Filling machine, Bag filter, Pumps, Zirconium Bead, 3 roll mill, and other accessories.

Our machines help you to make ideal products: paints, coatings, inks, pigments, dyes, thinner, hardener, emulsions, varnish, spin finish, putty, glues, adhesives, viscous pastes, concrete Admixtures,

PCVC solvent cement, liquid resins, sealants, silicone sealant, lithium battery, electronic slurry&paste, pulps, silicon dioxide, liquid rubber, pesticide, liquid fertilizer, disinfectant, liquid detergent, gel,

lotions, shampoo, body wash, liquid soap, hand sanitizer, liquid wash, nail polish, creams, and so on.

We could offer individual machine or full production lines for your plants.

5. What are advantages of your factory?

1) Our factory is a leader manufacture of Chemical machine With 18 years of Industry experience. We have a lot Technology Patents & Product Patents;

2) Our factory has Professional R&D Teams, High Technical Supports, Skilled Production Team, Reliable After Sales Service, Flexible Customized Solutions;

3) Our factory is the leader of this industry, named with high and new technology enterprise;

4) Our factory has plenty of industry experience, we could offer you the complete palnt planning.

6. Who are your factory's clients? Could you list some of them?

AKZONOBEL, JUNTON, PPG, NIPPON, DABAO, BURGER, MAYDOS, RAINBOW, HITECH COATING, CHINA PAINT, CHANGJIANG COATING, TOA, LYNWON PIGMENT,

PEONY INKS, TL INKS, ZR INKS, SAKATA INKS, KINGSWOO INKS, DIC INKS, ANLI, ACHILLES, REPOW GROUP, SHINETSU ADHESIVES, JUSHI, XINGLONG PESTICIDES...

7. What certificate your factory could offer?:

CE, BSC, CNEX, ISO, patents.

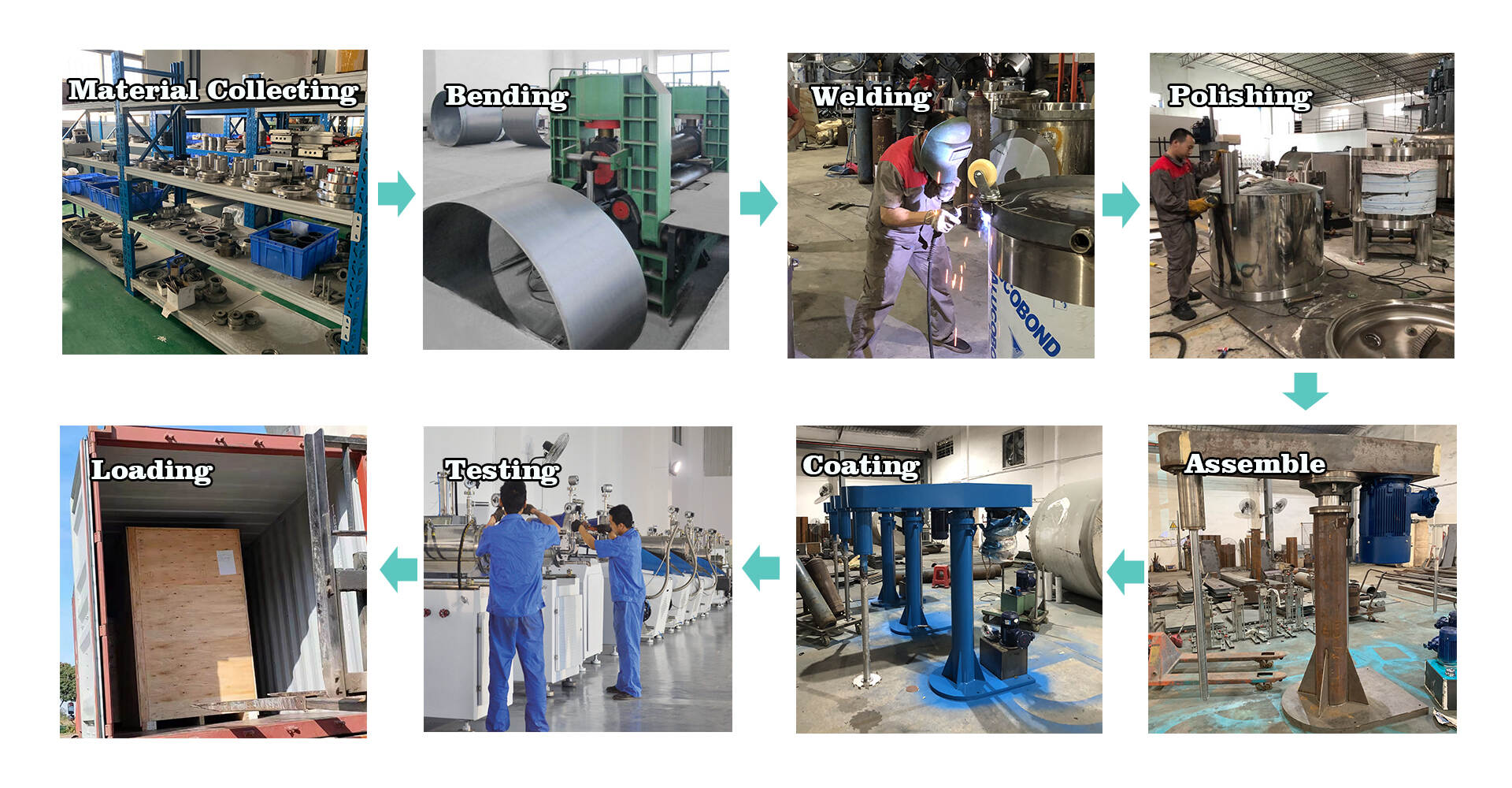

8. Manufacture Processing:

Our Chemical Machines are strictly quality control at every single production step, after quality past, we will move to do next step production.

Our Chemical Machines production process: raw materials preparing-cutting/bending materials-welding-polishing-assembling-coating-testing-packing-loading.

9. Packing And Shipping:

10. FAQ:

Question: Are you a factory or a trading company? where is your factory?

Answer: We are a real factory. Our factory is in fu'an industrial zone, leliu street, shunde ditrict, foshan city, guangdong province, China.

Question: Which countries your machine sold to?

Answer: American Market: America, Canada, Mexico, Brazil;

European Market: UK, Germany, Netherlands, Bulgaria, Italy, Russia;

African Market: South Africa, Algeria, Zambia, Cameroon, Ethiopia, Uganda, Madagascar;

Asian Market: Malaysia, Indonesia, Singapore, Vietnam, Thailand, Kazakhstan, Bangladesh, Pakistan, Lebanon, Iran, Iraq, Egypt, Qatar, Turkey, Saudi Arabia, UAE;

Question: How long is your machine warranty?

Answer: 12 months free for whole machine, After a year, spare parts charges, but life-long free for consultant.

Question: How long is your lead time?

Answer: Depends on the machines you choose. Generally from 7 days to 35days. Some big machine: 45-60days.

Question: How could I know how to operate the machines?

Answer: We provide teaching video and operating manual, and 24 hours in 7 days video guidance.

Question:How long is your machine warranty?

Answer: 12 months free for whole machine, After a year, spare parts charges, but life-long free for consultant.